TECHNICAL

INVESTIGATIONS

EXPERIMENTAL

General

There is no one-to-one correspondence between the mechanical

resistance of a column shoe as delivered and the mechanical resistance

of a column shoe connection. A connection is subjected to various action

effects like axial force, shear force, and bending moment in different

combinations, and the stiffness of the connection also has an impact on

the behavior and the design of the column. It is impossible to determine

the mechanical resistance or stiffness of a column shoe connection as a

set of values determined according to different standards and guidelines.

Therefore, these properties must be determined experimentally.

The EAD 1 summarizes the required tests and the related test setup,

and gives guidance on the evaluation of the test results. The values

determined in this way can then be used with the design method specified

in TR 068 2.

The following tests are mandatory according to EAD:

a) Bending Resistance Tests

b) Bending Stiffness Tests

c) Shear Resistance Tests

d) Fire Resistance investigations

a) Bending Resistance (BR) Tests

The target of the Bending Resistance (BR) tests is to show that the

resistance of the BOLDA® column shoe connection is at least equal to the

bending resistance of a monolithic cast-in-situ column.

b) Bending Stiffness (BS) Tests

In general, design of column-to-column or column-to-foundation

connections with column shoes should follow the design principles given

in EN 1992-1-1 for monolithic columns with continuous reinforcement. The

stiffness of columns and the moment-deflection-behavior respectively

is considered in EN 1992-1-1 by different buckling factors or buckling

lengths. Therefore, within these tests it is verified whether for column

shoe connections the same assumptions as for cast-in-situ columns apply.

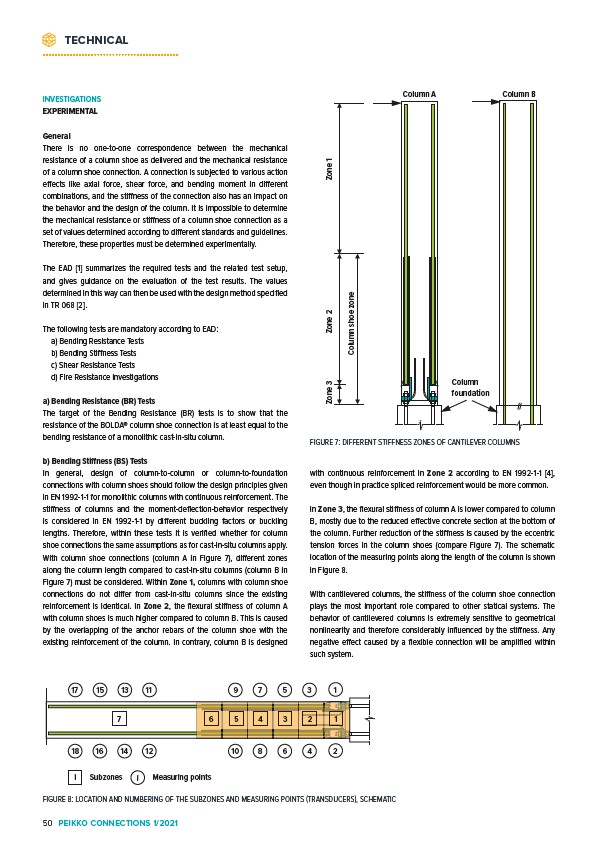

With column shoe connections (column A in Figure 7), different zones

along the column length compared to cast-in-situ columns (column B in

Figure 7) must be considered. Within Zone 1, columns with column shoe

connections do not differ from cast-in-situ columns since the existing

reinforcement is identical. In Zone 2, the flexural stiffness of column A

with column shoes is much higher compared to column B. This is caused

by the overlapping of the anchor rebars of the column shoe with the

existing reinforcement of the column. In contrary, column B is designed

Zone 2 Zone 1

Column shoe zone

Zone 3

Column A Column B

Column

foundation

FIGURE 7: DIFFERENT STIFFNESS ZONES OF CANTILEVER COLUMNS

with continuous reinforcement in Zone 2 according to EN 1992-1-1 4,

even though in practice spliced reinforcement would be more common.

In Zone 3, the flexural stiffness of column A is lower compared to column

B, mostly due to the reduced effective concrete section at the bottom of

the column. Further reduction of the stiffness is caused by the eccentric

tension forces in the column shoes (compare Figure 7). The schematic

location of the measuring points along the length of the column is shown

in Figure 8.

With cantilevered columns, the stiffness of the column shoe connection

plays the most important role compared to other statical systems. The

behavior of cantilevered columns is extremely sensitive to geometrical

nonlinearity and therefore considerably influenced by the stiffness. Any

negative effect caused by a flexible connection will be amplified within

such system.

17 15 13 11 9 7 5 3

7

Column A

6 5 4 3 2 1

18 16 14 12

i Subzones i Measuring points

1

10 8 6 4 2

FIGURE 8: LOCATION AND NUMBERING OF THE SUBZONES AND MEASURING POINTS (TRANSDUCERS), SCHEMATIC

50 PEIKKO CONNECTIONS 1/2021