A European Technical Assessment is issued by a Technical Assessment

Body (TAB). The European TABs are organized in the European

Organization for Technical Assessment (EOTA).

Based on an ETA, a certificate of constancy of performance and a

declaration of performance (DoP) of the manufacturer, a CE marking

may be affixed to the products. In the current phase of change, national

approvals, European Technical Approvals (ETA "old"), and European

Technical Assessments (ETA "new") are available for various product

groups. CE marking is therefore a declaration that the product meets

certain safety requirements such as mechanical and/or fire resistances.

The application for a European Technical Assessment of EOTA (ETA) and

the associated CE marking is voluntary. The ETA contains all required

characteristic values, which have been obtained and verified according to

the recognized rules of technology. It is the unique opportunity to describe

the performance characteristics of column shoe systems.

Peikko's approach is much more comprehensive – not only the safetyrelevant

properties of a product are in focus, but also the corresponding

technical rules and dimensioning regulations are constantly improved

and further developed with the aim of providing faster and more efficient

system solutions for the user. This supports further development of

reinforced concrete construction in the long run.

BOLDA® COLUMN SHOES

GEOMETRY

BOLDA® column shoe connections are used to create cost-effective

moment resisting stiff connections between precast concrete columns

and foundations, or between precast concrete columns.

The system consists of column shoes and corresponding anchor bolts.

Column shoes are cast into precast a concrete column, whereas anchor

bolts are cast into foundation or another column. On construction site, the

columns are erected on the anchor bolts, adjusted on the correct level and

vertical position, and fixed to the bolts. Finally, the joint between column

and base structure is grouted (Figure 2).

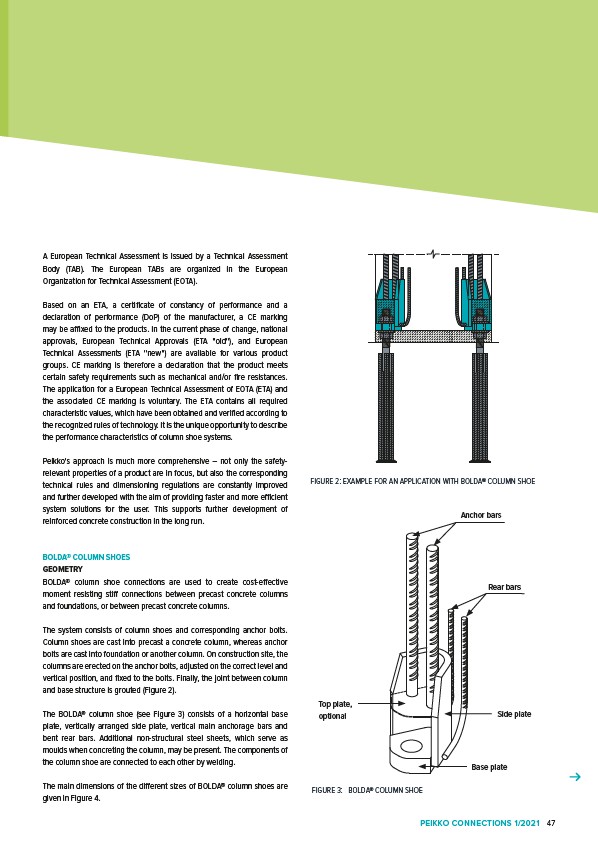

The BOLDA® column shoe (see Figure 3) consists of a horizontal base

plate, vertically arranged side plate, vertical main anchorage bars and

bent rear bars. Additional non-structural steel sheets, which serve as

moulds when concreting the column, may be present. The components of

the column shoe are connected to each other by welding.

The main dimensions of the different sizes of BOLDA® column shoes are

given in Figure 4.

FIGURE 2: EXAMPLE FOR AN APPLICATION WITH BOLDA® COLUMN SHOE

FIGURE 3: BOLDA® COLUMN SHOE

Anchor bars

Top plate,

optional

Rear bars

Side plate

Base plate

PEIKKO CONNECTIONS 1/2021 47