TECHNICAL

SUMMARY OF THE RESULTS

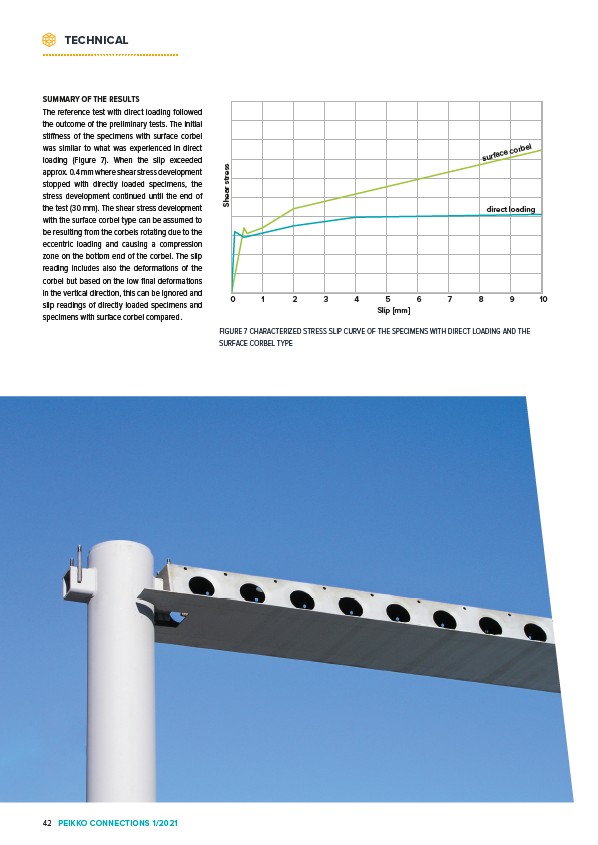

The reference test with direct loading followed

the outcome of the preliminary tests. The initial

stiffness of the specimens with surface corbel

was similar to what was experienced in direct

loading (Figure 7). When the slip exceeded

approx. 0.4 mm where shear stress development

stopped with directly loaded specimens, the

stress development continued until the end of

the test (30 mm). The shear stress development

with the surface corbel type can be assumed to

be resulting from the corbels rotating due to the

eccentric loading and causing a compression

zone on the bottom end of the corbel. The slip

reading includes also the deformations of the

corbel but based on the low final deformations

in the vertical direction, this can be ignored and

slip readings of directly loaded specimens and

specimens with surface corbel compared.

direct loading

Shear stress

0 1 2 3 4 5 6 7 8 9 10

Slip mm

surface corbel

FIGURE 7 CHARACTERIZED STRESS SLIP CURVE OF THE SPECIMENS WITH DIRECT LOADING AND THE

SURFACE CORBEL TYPE

42 PEIKKO CONNECTIONS 1/2021