TEST SERIES

INTRODUCTION

The scope of the test series was to broaden

the knowledge regarding the load transfer

behavior of a composite column in the vicinity

of the load introduction. The main principles

are available from the standards and from

the literature, but design of an advanced joint

requires assumptions which are critical to

overall behavior. These tests were to examine

those assumptions.

Where the preliminary tests concentrated on the

principals of the shear transfer, the later tests

with the corbels were to provide information

about the behavior of a specific joint type. The

specimens and the loading setup were planned

so that they would represent a composite

section taken out from a typical continuous

multi story column.

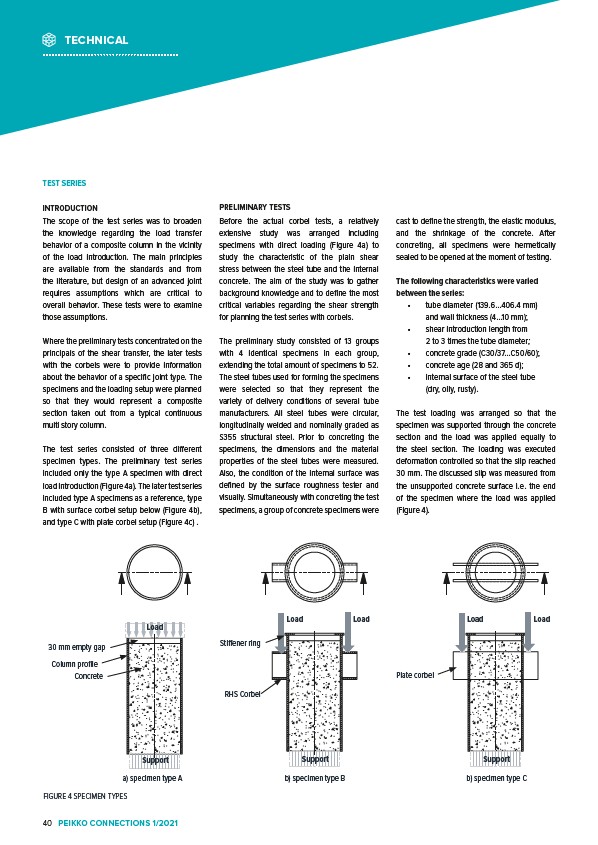

The test series consisted of three different

specimen types. The preliminary test series

included only the type A specimen with direct

load introduction (Figure 4a). The later test series

included type A specimens as a reference, type

B with surface corbel setup below (Figure 4b),

and type C with plate corbel setup (Figure 4c) .

PRELIMINARY TESTS

Before the actual corbel tests, a relatively

extensive study was arranged including

specimens with direct loading (Figure 4a) to

study the characteristic of the plain shear

stress between the steel tube and the internal

concrete. The aim of the study was to gather

background knowledge and to define the most

critical variables regarding the shear strength

for planning the test series with corbels.

The preliminary study consisted of 13 groups

with 4 identical specimens in each group,

extending the total amount of specimens to 52.

The steel tubes used for forming the specimens

were selected so that they represent the

variety of delivery conditions of several tube

manufacturers. All steel tubes were circular,

longitudinally welded and nominally graded as

S355 structural steel. Prior to concreting the

specimens, the dimensions and the material

properties of the steel tubes were measured.

Also, the condition of the internal surface was

defined by the surface roughness tester and

visually. Simultaneously with concreting the test

specimens, a group of concrete specimens were

cast to define the strength, the elastic modulus,

and the shrinkage of the concrete. After

concreting, all specimens were hermetically

sealed to be opened at the moment of testing.

The following characteristics were varied

between the series:

• tube diameter (139.6…406.4 mm)

and wall thickness (4…10 mm);

• shear introduction length from

2 to 3 times the tube diameter;

• concrete grade (C30/37…C50/60);

• concrete age (28 and 365 d);

• internal surface of the steel tube

(dry, oily, rusty).

The test loading was arranged so that the

specimen was supported through the concrete

section and the load was applied equally to

the steel section. The loading was executed

deformation controlled so that the slip reached

30 mm. The discussed slip was measured from

the unsupported concrete surface i.e. the end

of the specimen where the load was applied

(Figure 4).

a) specimen type A

30 mm empty gap

Column profile

FIGURE 4 SPECIMEN TYPES

Plate corbel

RHS Corbel

Load Load Load Load

b) specimen type B b) specimen type C

Concrete

Stiffener ring

Load

Support Support Support

TECHNICAL

40 PEIKKO CONNECTIONS 1/2021