DESIGN OF THE PILESUPPORTED

SLAB FOR THE

KIRISMÄKI INTERCHANGE

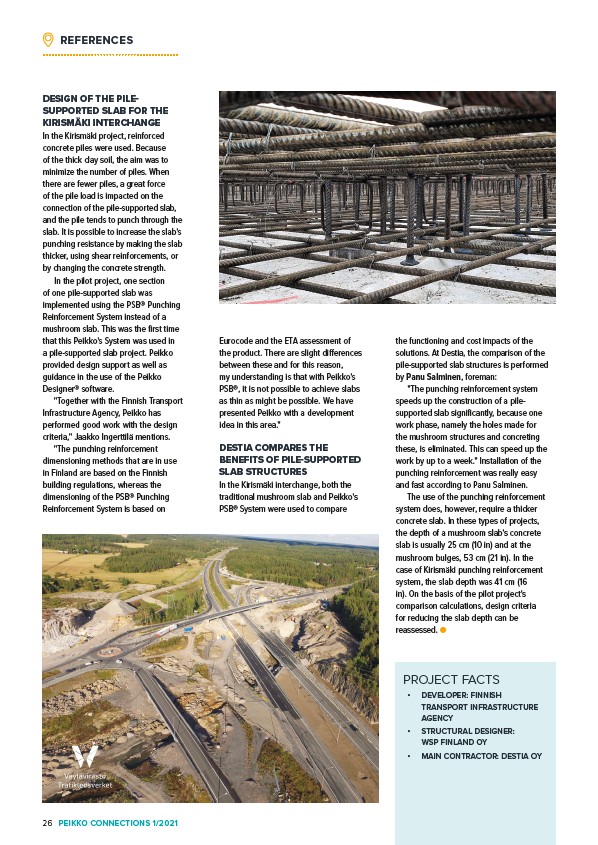

In the Kirismäki project, reinforced

concrete piles were used. Because

of the thick clay soil, the aim was to

minimize the number of piles. When

there are fewer piles, a great force

of the pile load is impacted on the

connection of the pile-supported slab,

and the pile tends to punch through the

slab. It is possible to increase the slab's

punching resistance by making the slab

thicker, using shear reinforcements, or

by changing the concrete strength.

In the pilot project, one section

of one pile-supported slab was

implemented using the PSB® Punching

Reinforcement System instead of a

mushroom slab. This was the first time

that this Peikko's System was used in

a pile-supported slab project. Peikko

provided design support as well as

guidance in the use of the Peikko

Designer® software.

"Together with the Finnish Transport

Infrastructure Agency, Peikko has

performed good work with the design

criteria," Jaakko Ingerttilä mentions.

"The punching reinforcement

dimensioning methods that are in use

in Finland are based on the Finnish

building regulations, whereas the

dimensioning of the PSB® Punching

Reinforcement System is based on

PROJECT FACTS

• DEVELOPER: FINNISH

TRANSPORT INFRASTRUCTURE

AGENCY

• STRUCTURAL DESIGNER:

WSP FINLAND OY

• MAIN CONTRACTOR: DESTIA OY

Eurocode and the ETA assessment of

the product. There are slight differences

between these and for this reason,

my understanding is that with Peikko's

PSB®, it is not possible to achieve slabs

as thin as might be possible. We have

presented Peikko with a development

idea in this area."

DESTIA COMPARES THE

BENEFITS OF PILE-SUPPORTED

SLAB STRUCTURES

In the Kirismäki interchange, both the

traditional mushroom slab and Peikko's

PSB® System were used to compare

the functioning and cost impacts of the

solutions. At Destia, the comparison of the

pile-supported slab structures is performed

by Panu Salminen, foreman:

"The punching reinforcement system

speeds up the construction of a pilesupported

slab significantly, because one

work phase, namely the holes made for

the mushroom structures and concreting

these, is eliminated. This can speed up the

work by up to a week." Installation of the

punching reinforcement was really easy

and fast according to Panu Salminen.

The use of the punching reinforcement

system does, however, require a thicker

concrete slab. In these types of projects,

the depth of a mushroom slab's concrete

slab is usually 25 cm (10 in) and at the

mushroom bulges, 53 cm (21 in). In the

case of Kirismäki punching reinforcement

system, the slab depth was 41 cm (16

in). On the basis of the pilot project's

comparison calculations, design criteria

for reducing the slab depth can be

reassessed. ●

REFERENCES

26 PEIKKO CONNECTIONS 1/2021