TECHNICAL

DISASSEMBLY TESTS

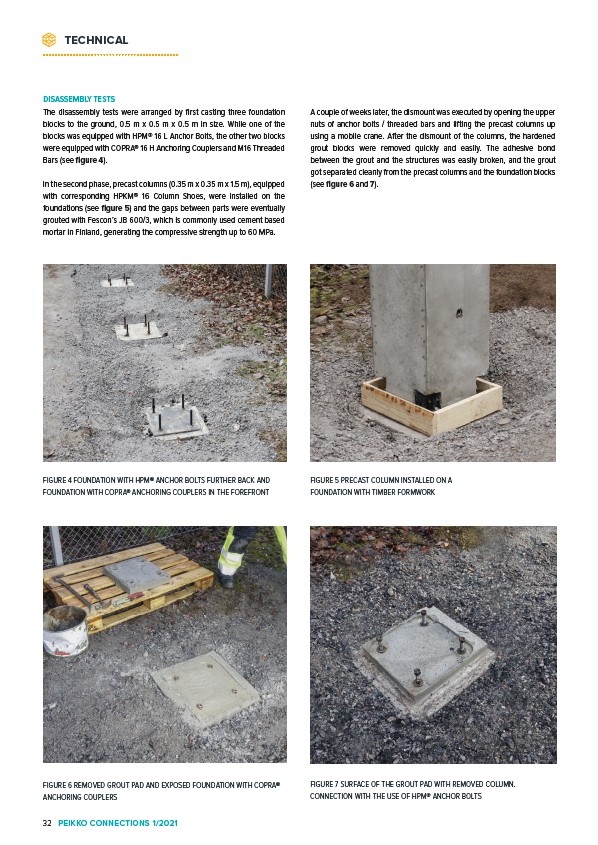

The disassembly tests were arranged by first casting three foundation

blocks to the ground, 0.5 m x 0.5 m x 0.5 m in size. While one of the

blocks was equipped with HPM® 16 L Anchor Bolts, the other two blocks

were equipped with COPRA® 16 H Anchoring Couplers and M16 Threaded

Bars (see figure 4).

In the second phase, precast columns (0.35 m x 0.35 m x 1.5 m), equipped

with corresponding HPKM® 16 Column Shoes, were installed on the

foundations (see figure 5) and the gaps between parts were eventually

grouted with Fescon’s JB 600/3, which is commonly used cement based

mortar in Finland, generating the compressive strength up to 60 MPa.

A couple of weeks later, the dismount was executed by opening the upper

nuts of anchor bolts / threaded bars and lifting the precast columns up

using a mobile crane. After the dismount of the columns, the hardened

grout blocks were removed quickly and easily. The adhesive bond

between the grout and the structures was easily broken, and the grout

got separated cleanly from the precast columns and the foundation blocks

(see figure 6 and 7).

FIGURE 4 FOUNDATION WITH HPM® ANCHOR BOLTS FURTHER BACK AND

FOUNDATION WITH COPRA® ANCHORING COUPLERS IN THE FOREFRONT

FIGURE 5 PRECAST COLUMN INSTALLED ON A

FOUNDATION WITH TIMBER FORMWORK

FIGURE 6 REMOVED GROUT PAD AND EXPOSED FOUNDATION WITH COPRA®

ANCHORING COUPLERS

FIGURE 7 SURFACE OF THE GROUT PAD WITH REMOVED COLUMN.

CONNECTION WITH THE USE OF HPM® ANCHOR BOLTS

32 PEIKKO CONNECTIONS 1/2021