Load kN - displacement mm

kN

400

350

300

250

200

150

100

50

0

Load kN - displacement mm

diagram

HPM® Anchor Bolt

COPRA® Anchoring Coupler

diagram

0 10 20 30

mm

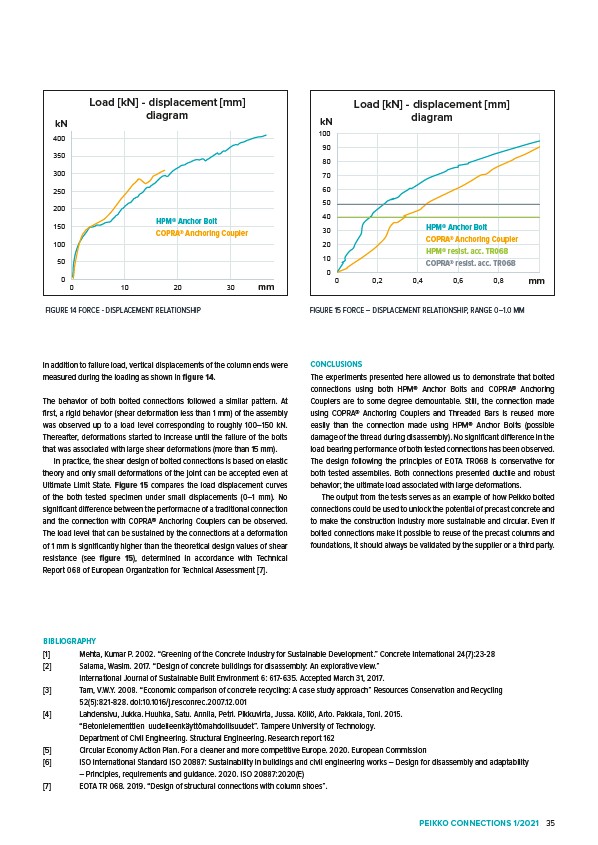

In addition to failure load, vertical displacements of the column ends were

measured during the loading as shown in figure 14.

The behavior of both bolted connections followed a similar pattern. At

first, a rigid behavior (shear deformation less than 1 mm) of the assembly

was observed up to a load level corresponding to roughly 100–150 kN.

Thereafter, deformations started to increase until the failure of the bolts

that was associated with large shear deformations (more than 15 mm).

In practice, the shear design of bolted connections is based on elastic

theory and only small deformations of the joint can be accepted even at

Ultimate Limit State. Figure 15 compares the load displacement curves

of the both tested specimen under small displacements (0–1 mm). No

significant difference between the performacne of a traditional connection

and the connection with COPRA® Anchoring Couplers can be observed.

The load level that can be sustained by the connections at a deformation

of 1 mm is significantly higher than the theoretical design values of shear

resistance (see figure 15), determined in accordance with Technical

Report 068 of European Organization for Technical Assessment 7.

Load kN - displacement mm

kN

100

90

80

70

60

50

40

30

20

10

Load kN - displacement mm

diagram

100

90

80

70

60

50

40

30

20

10

diagram

HPM® Anchor Bolt

COPRA® Anchoring Coupler

HPM® resist. acc. TR068

COPRA® resist. acc. TR068

CONCLUSIONS

The experiments presented here allowed us to demonstrate that bolted

connections using both HPM® Anchor Bolts and COPRA® Anchoring

Couplers are to some degree demountable. Still, the connection made

using COPRA® Anchoring Couplers and Threaded Bars is reused more

easily than the connection made using HPM® Anchor Bolts (possible

damage of the thread during disassembly). No significant difference in the

load bearing performance of both tested connections has been observed.

The design following the principles of EOTA TR068 is conservative for

both tested assemblies. Both connections presented ductile and robust

behavior; the ultimate load associated with large deformations.

The output from the tests serves as an example of how Peikko bolted

connections could be used to unlock the potential of precast concrete and

to make the construction industry more sustainable and circular. Even if

bolted connections make it possible to reuse of the precast columns and

foundations, it should always be validated by the supplier or a third party.

BIBLIOGRAPHY

1 Mehta, Kumar P. 2002. “Greening of the Concrete Industry for Sustainable Development.” Concrete International 24(7):23-28

2 Salama, Wasim. 2017. “Design of concrete buildings for disassembly: An explorative view.”

International Journal of Sustainable Built Environment 6: 617-635. Accepted March 31, 2017.

3 Tam, V.W.Y. 2008. “Economic comparison of concrete recycling: A case study approach” Resources Conservation and Recycling

52(5):821-828. doi:10.1016/j.resconrec.2007.12.001

4 Lahdensivu, Jukka. Huuhka, Satu. Annila, Petri. Pikkuvirta, Jussa. Köliö, Arto. Pakkala, Toni. 2015.

“Betonielementtien uudelleenkäyttömahdollisuudet”. Tampere University of Technology.

Department of Civil Engineering. Structural Engineering. Research report 162

5 Circular Economy Action Plan. For a cleaner and more competitive Europe. 2020. European Commission

6 ISO International Standard ISO 20887: Sustainability in buildings and civil engineering works – Design for disassembly and adaptability

– Principles, requirements and guidance. 2020. ISO 20887:2020(E)

7 EOTA TR 068. 2019. “Design of structural connections with column shoes”.

mm

0

0 0,2 0,4 0,6 0,8

FIGURE 14 FORCE - DISPLACEMENT RELATIONSHIP

400

350

300

250

200

150

100

50

0

0 10 20 30

kN

mm

kN

mm

0

0 0,2 0,4 0,6 0,8

FIGURE 15 FORCE – DISPLACEMENT RELATIONSHIP, RANGE 0–1.0 MM

PEIKKO CONNECTIONS 1/2021 35