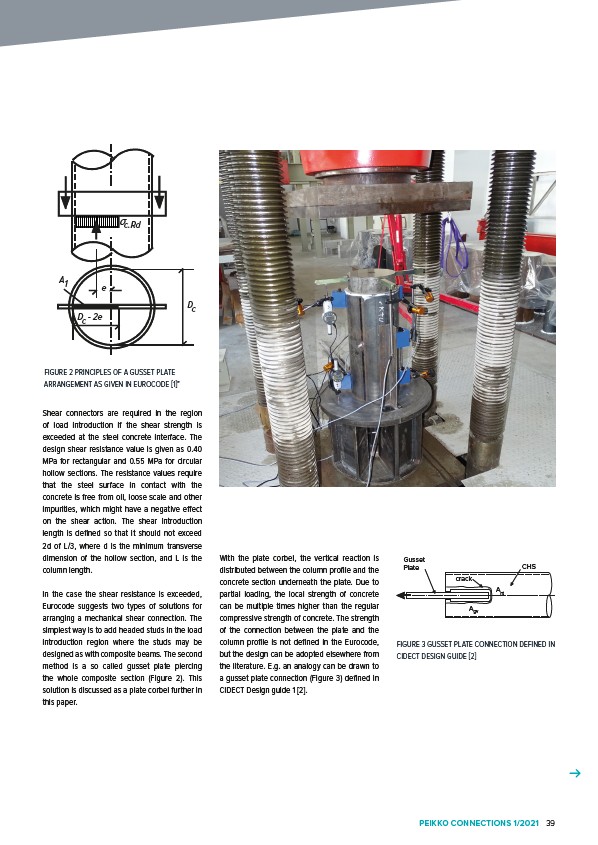

FIGURE 2 PRINCIPLES OF A GUSSET PLATE

ARRANGEMENT AS GIVEN IN EUROCODE 1”

Shear connectors are required in the region

of load introduction if the shear strength is

exceeded at the steel concrete interface. The

design shear resistance value is given as 0.40

MPa for rectangular and 0.55 MPa for circular

hollow sections. The resistance values require

that the steel surface in contact with the

concrete is free from oil, loose scale and other

impurities, which might have a negative effect

on the shear action. The shear introduction

length is defined so that it should not exceed

2d of L/3, where d is the minimum transverse

dimension of the hollow section, and L is the

column length.

In the case the shear resistance is exceeded,

Eurocode suggests two types of solutions for

arranging a mechanical shear connection. The

simplest way is to add headed studs in the load

introduction region where the studs may be

designed as with composite beams. The second

method is a so called gusset plate piercing

the whole composite section (Figure 2). This

solution is discussed as a plate corbel further in

this paper.

Gusset

Plate CHS

crack

Ant

Agv

FIGURE 3 GUSSET PLATE CONNECTION DEFINED IN

CIDECT DESIGN GUIDE 2

With the plate corbel, the vertical reaction is

distributed between the column profile and the

concrete section underneath the plate. Due to

partial loading, the local strength of concrete

can be multiple times higher than the regular

compressive strength of concrete. The strength

of the connection between the plate and the

column profile is not defined in the Eurocode,

but the design can be adopted elsewhere from

the literature. E.g. an analogy can be drawn to

a gusset plate connection (Figure 3) defined in

CIDECT Design guide 1 2.

A1 e

c.Rd

Dc

Dc - 2e

PEIKKO CONNECTIONS 1/2021 39